Wondering how toilets are made? See more in modern factories—from raw materials to final testing. Learn every step of the toilet manufacturing process.

1. Introduction: How Are Toilets Made?

Toilets are one of the most essential inventions in modern human history—used every day, yet rarely do we think about how they’re actually made. Behind each sleek ceramic bowl is a sophisticated manufacturing process involving natural materials, precise engineering, and rigorous testing. Whether you’re a curious learner, a plumbing enthusiast, or an industry professional, understanding how toilets are made offers a fascinating look into industrial ceramics and smart product design.

In this guide, we’ll break down the entire toilet manufacturing process, from clay and slip casting to firing in high-temperature kilns and final product testing. Along the way, you’ll learn why porcelain is the material of choice, how eco-friendly designs are revolutionizing toilet production, and what makes a high-quality, long-lasting toilet.

2. How Are Toilets Made? A Step-by-Step Look Inside the Manufacturing Process

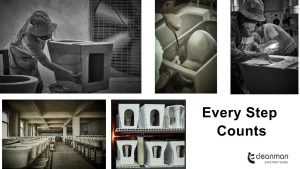

Toilets are everyday essentials, yet few people know the precision and craftsmanship involved in their creation. At Cleanman, a 23-year-old ceramic toilet factory, we combine traditional ceramic techniques with modern smart technology to build toilets that are durable, efficient, and eco-friendly.

In this article, we walk you through the complete toilet production process—from the raw clay to the final boxed product—based on actual factory procedures used at Cleanman’s facilities. You can watch the video if you don’t want to read so many steps.

2.1 Product Design

The process starts at the design table. Engineers and designers work together to ensure the toilet’s shape supports:

-

Efficient flushing

-

Comfortable ergonomics

-

Aesthetic harmony with modern bathrooms

Designs are modeled in 3D software, then tested for water flow, splash reduction, and space optimization.

2.2 Mold Making

Once the design is finalized, custom molds are produced. These molds will shape the toilet during casting.

Mold Prep Steps:

- Clean the mold, wiping the slip side with slurry.

- Apply talcum powder to double-sided slip zones to avoid sticking.

- Assemble the mold for the slip-casting process.

2.3 Slip Formulation and Preparation

Toilets are made primarily from vitreous china—a mixture of clay, feldspar, quartz, and water.

At Cleanman:

-

The slip is filtered with fine sand.

-

A sand pump ensures no air bubbles enter.

-

Slip is filled into molds until full. No empty slip areas are allowed.

☑️ This step is critical to avoid micro-cracks and weak spots.

2.4 Working Mold and Slip Casting

In this stage:

-

Slip is poured into the mold and forms a 1.0mm wall thickness.

-

Thickness is checked at the injection hole.

-

Excess slip is drained and returned to the tank.

Once the slip forms a hardened shell:

-

Remove the mold panel.

-

Patch cracks.

-

Drill inlet and outlet water holes.

-

Ensure no slurry sticks to internal surfaces.

2.5 Trimming and Initial Assembly

After moderate drying, the body is flipped and:

-

Cracks and leaks are patched

-

The foot mold is opened and reinstalled

-

The outlet base is fixed to the bottom

This phase requires skilled hands to ensure structural integrity.

2.6 Drying and Assembly

The toilet is completely demolded, trimmed, and patched:

-

Remove casting lines

-

Apply slurry to the tank mouth

-

Reinstall the tank for the second round of drying

The body is placed on a drying rack and:

-

Cracked areas are wrapped with paper and cloth

-

Drill the tank base to level the slurry

-

2.7 Inspection

Before glazing, Cleanman conducts:

-

Thickness checks

-

Crack inspections

-

Sand hole drilling

-

Surface smoothing

-

Qualification marking

This ensures only flawless units move forward.

2.8 Glazing

The body is coated in a glassy white glaze, which:

-

Seals the porous ceramic

-

Adds smoothness and shine

-

Prevents staining

Key steps include:

-

Trimming final lines

-

Applying slurry and clay caps

-

Leveling seams

-

Pre-drying in a special room

2.9 Loading into kilns

Glazed toilets are loaded into kilns on trays:

-

Technicians check slip thickness and surface details

-

Products are marked and cataloged

Cleanman uses smart tracking for product traceability from the kiln to the warehouse.

2.10 Kiln Firing

Toilets are fired at ~1270°C:

-

This vitrifies the ceramic, making it strong and durable

-

Low temperatures avoid yellowing

-

Proper temps prevent blue smoke, ensuring a perfect white finish

2.11 Post-Firing Inspection

After cooling:

-

Ceramics are unloaded and stacked on trays

-

Accessories are packed with each product

-

Only certified, flawless products pass to packaging

-

2.12 Packaging and Storage

Each unit is:

Water-tested

Dried and cleaned

Covered with plastic film

Boxed, labeled with color and pit distance, then stored

Cleanman uses eco-friendly recyclable packaging to reduce environmental impact.

📊 Toilet Manufacturing Process Summary Table

| Step | Process Name (EN) | Description |

|---|---|---|

| 1 | Product Design | 3D modeling for function, style, and water efficiency |

| 2 | Mold Making | Clean, prep, and assemble molds for slip casting |

| 3 | Slip Formulation | Mix clay, silica, and water into a smooth, air-free slurry |

| 4 | Slip Preparation | Filtered and pumped to prevent bubbles |

| 5 | Working Mold & Casting | Fill mold with slip; drain once 1.0mm thick |

| 6 | Initial Demolding | Open mold, patch cracks, and drill water inlets |

| 7 | Trimming | Patch defects, install outlet base, and foot mold |

| 8 | Drying | Fully demold, apply slurry to the tank mouth, reattach |

| 9 | Pre-Glaze Inspection | Flip body, level tank base, wrap cracked areas |

| 10 | Glazing | Apply glaze, drill sand holes, and dry seams |

| 11 | Loading | Inspect, mark, and record the product code for tracking |

| 12 | Kiln Firing | Fire at 1270°C for vitrification and strength |

| 13 | Post-Fire Inspection | Stack and pack finished ceramic bodies |

| 14 | Packaging & Storage | Water-test, dry, clean, bag, label, and box |

Sustainable & Smart Toilet Innovations

Modern manufacturing at Cleanman isn’t just about tradition—it’s about innovation:

-

Dual-flush technology for water saving

-

Smart bidet integration with hygiene sensors

-

Eco-certified kilns and energy-efficient drying rooms

Learn more about our green practices on the Cleanman sustainability page.

3. FAQs Regarding “How Are Toilets Made”

-

Why are toilets usually white?

White represents cleanliness and is easier to inspect for hygiene. The color also reflects the natural hue of porcelain glaze. However, we also provide matt color toilets years ago. It is already a very mature technology.

-

Can toilets be recycled?

Yes! Old toilets can be broken down and reused as roadbed material or construction aggregate.

-

What is vitreous china?

A ceramic material that’s glazed and fired at high temperatures—perfect for durability and water resistance.

-

How long does it take to make a toilet?

With a ready mold, it typically takes 14 days from casting to the finished toilet, including drying and firing. However, if the weather is too wet or too cold, it will take longer.

For OEM orders, it takes about 40 days, including assembly, inspection, and packaging.

4. About Cleanman

Cleanman is one of China’s premier manufacturers of commercial and residential sanitation products. With a presence in over 100 areas, we produce:

-

Smart toilets

-

Urinals

-

Washroom accessories

-

Custom OEM solutions

Visit our official website for catalogs, case studies, and product innovations.

5. Final Thoughts

Toilets are often overlooked, but their production is a highly refined blend of material science, engineering, and hand-finishing expertise. At Cleanman, we ensure that each toilet undergoes over 14 carefully monitored steps, from slip casting to inspection, delivering lasting performance and clean design to homes and businesses worldwide.

6. Toilet Buyer’s Checklist

Whether you’re a homeowner, hotel operator, or project manager, here’s what to look for when buying a toilet:

| ✅ Item | Why It Matters |

|---|---|

| 🚽 Toilet Type | One-piece, two-piece, or wall-mounted – affects installation & design |

| 💧 Flush Type | Be clear about what you need: top flush (single flush or dual flush), side flush.

And don’t make mistakes about litres, is it 4L, 6L, or 4.8L> |

| 🧼 Material | Vitreous china is durable and easy to clean.

Seat cover: there are two types- UF or PP. Price varies |

| 🌿 Water Efficiency | Are you looking for WaterSense-certified or low-flow models? |

| 🧠 Smart Features

(Applicable to smart toilets only) |

Bidet, auto-flush, heated seats, touchless tech. For more models, please visit our branch, Vleeo Smart Toilet. |

| 📏 Bowl Shape | Elongated is comfier; round is compact |

| ⚙️ Rough-In Size | It varies from country to country, including P-trap 180, and S-trap 250mm or 300 mm. |

| 🧰 Installation Needs | Wall vs floor standing, seat height, and DIY compatibility.

Be sure that you will get the installation kit and manual. |

| 🧪 Certification | If needed, please check if the toilet is certified according to your country’s regulations, like cUPC for North America, Watermark for Australia, etc.

CE for Europe, WaterMark for Australia, etc. |

| 💼 Manufacturer Support | Warranty, spare parts, and service availability. |

| 🔍 Inspection Test Passed | Confirm water testing, sealing, and quality marks |

At Cleanman, we offer our B2B buyers all guides for the above points, including product selling points, installation manuals, and video etc. Contact us for more.